RD10 CNC Tube Bender

Model #: 21406

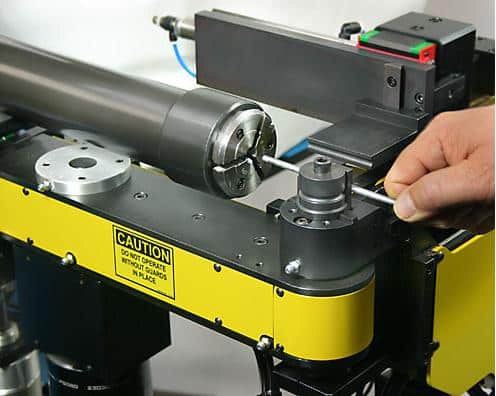

The RD10 bends stainless steel up to Ø10mm (3/8”) using a rotary draw process. This technique has proven to be effective for tight radius bending. The collet closer that holds the tubing during the bending process makes use of 80 PSI shop air. This ensures the tube is help tight before, during, and after a plane rotation. The design of the carriage spindle allows the end of the tubing to get right up next to the bend tooling on the very last bend. This often translates into avoiding a trimming operation after bending.

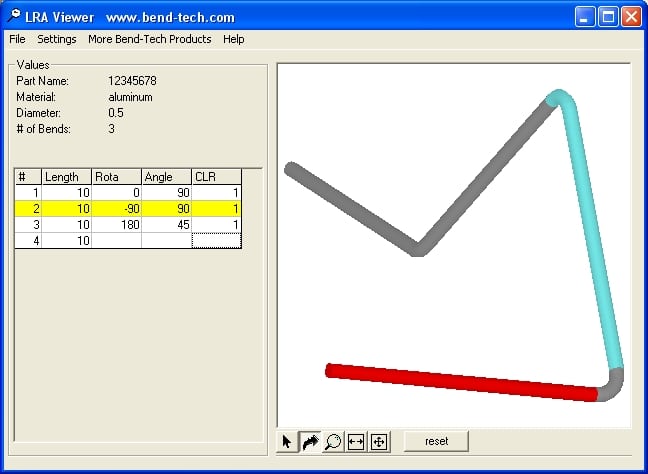

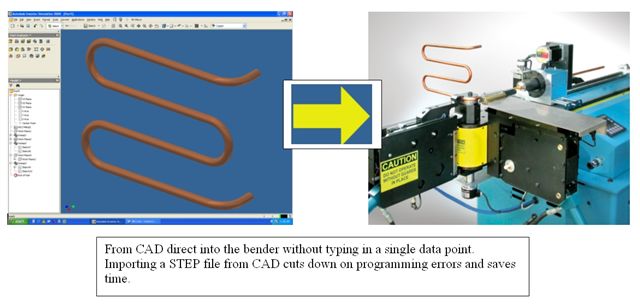

Software features include hitch feed, pause before bend, XYZ to LRA conversion, interference checking, 3 axis per bend speed settings, and more. An optional STEP file converter allows a user to read in a CAD generated STEP file direct from CAD right into the bender’s controller. No need to type in the tube’s bend data standing at the RD10, go ahead and read in the 3 dimensional bend data direct from your CAD system. It’s that simple.

The RD10 is a fast, accurate, and repeatable CNC tube bender. Designed and built in the US, this small diameter CNC bender is production ready. Give us a call with your application. We are motivated to help you reduce your cost of goods sold.

Product Video & Details

Customers using Internet Explorer may have difficulty viewing the online training videos.

We suggest using Chrome, Safari, Microsoft Edge, or another modern internet browser to view our videos. To find out more about the system requirements to view our training videos, and to see if your device meets them, click here.

Safety

Features

- Capacity: 10mm OD steel tubing

- All electric servo driven

- Runs on Windows-based platform

- Able to end chuck or hitch feed

- Tube bender users the rotary draw process

- Safety mat with interlock swing arm guards

- Optional mandrel bending available

- Manual loading – Standard

- STEP file converter used to import CAD files directly into bender – optional

- Safety mat included

- Safety swing arm guards included with standard electrical interlock

- Bend head guards included

- Optional dual stack bending

- 80 PSI shop air required

- 3D Model Viewer for LRA Data Verification – Optional

- Magazine loader – Optional

Inquire About This Product